Disassembly of movement:

© 2016 Gary Fields

This movement, from a very nice Daneker wall clock, came to me from a customer, wanting Butterbearings™ installed up and to the center wheel arbor. This will be a pictorial essay and diary of this work, and of other clock and watch movements as I work on them to repair, restore, and improve them with what I am able to do. I hope you enjoy this blog!........................gf

Front of movement

Front mounting plate removed, exposing winding arbor and stopworks and hour and minute train

Stopworks exposed

Retainer clip removed

Hour wheel removed.

Stopworks removed

Back plate with mainspring retainer

Mainspring retainer and winding arbor removed

Exposing some of the inner wheel work

Spacing posts removed

Side view of minute arbor with tension spring, washers, and tension/retainer nut

Spring, washers and nut removed

Starting to remove minute arbor

Minute arbor removed out through front

Small pin lever bridge with screw retainer

View from top showing pin lever and balance wheel in place

Pin lever and balance removed

Movement nuts removed

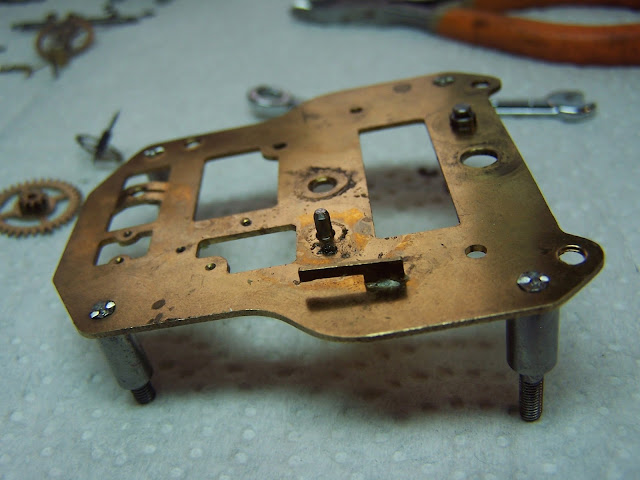

Back movement plate removed showing wheels in place

Third wheel removal

Second wheel removed

Sixth wheel removed

Escape wheel removed

Fifth wheel removed

Center wheel removed

Minute wheel and retainer

Minute wheel retainer swung aside

Minute wheel removed

The movement in her bare essentials. Trip to the ultrasonic is next.

Things noted during tear down:

> Lots of dried semi-hard grease, some exhibiting verdigris development albeit not serious or in large size.

> Excessive slop in pivots, especially up past center wheel, where there is less force on them. Dried oil exacerbates this problem.

> No visible damage or wear (gouging, grooves, pitting) noted on any pivots.

> No nickel plating observed on any steel surface

> Wheel teeth all appear to be in excellent shape.

Post ultrasonic cleaning:

> Worn pivot holes easily visible, especially in upper end wheels. Will take some pictures tomorrow against white background, easily shows the wear.

> Ultrasonic cleaning accomplished using 1 1/2 gal. of Walmart ammonia cleaner, 1 pint of Pine Sol cleaner. Mildly heated, with clean time of 5 minutes in an L&R Quantrex 280H ultrasonic cleaner. Rinsed in reverse osmosis water (less stains on brass), and dried by forced air heat.